Wood-plastic composite board is a kind of wood-plastic composite board which is mainly made of wood (wood cellulose, plant cellulose) as the basic material, thermoplastic polymer material (plastic) and processing aids, etc., mixed evenly and then heated and extruded by mold equipment. The high-tech green environmental protection material has both the properties and characteristics of wood and plastic. It is a new type of environmentally friendly high-tech material that can replace wood and plastic. Its English Wood Plastic Composites is abbreviated as WPC.

![]()

Physical properties

good strength, high hardness, non-slip, wear-resistant, no cracking, no moth-eaten, low water absorption, aging resistance, corrosion resistance, antistatic and ultraviolet rays, insulation, heat insulation, flame retardant, can resist 75 ℃ High temperature and low temperature of -40°C.

![]()

Environmental performance

Ecological wood, environmentally friendly wood, renewable, free of toxic substances, dangerous chemical components, preservatives, etc., no release of formaldehyde, benzene and other harmful substances, no air pollution and environmental pollution, can be 100% recycled It is also biodegradable for reuse and reprocessing.

![]()

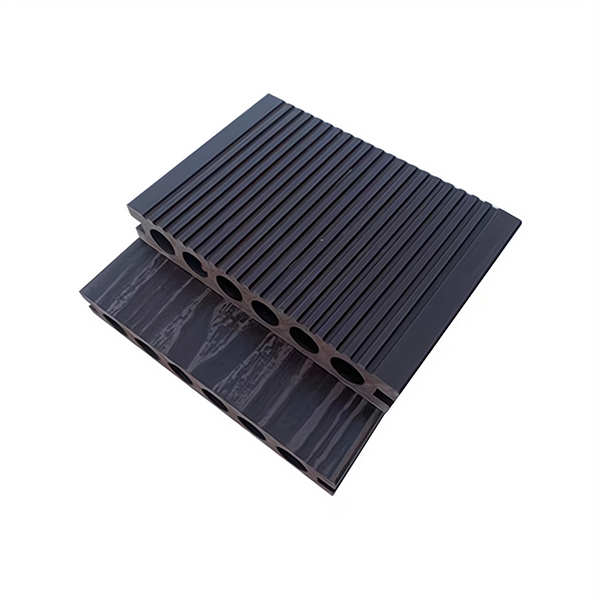

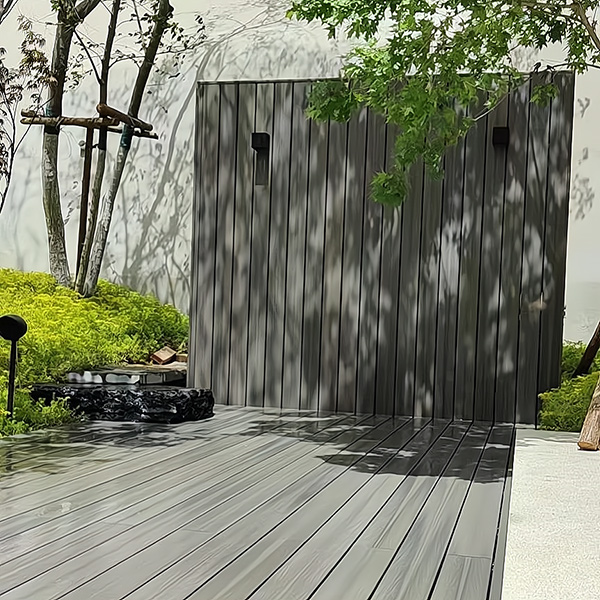

Appearance and texture

It has the natural appearance and texture of wood. It has better dimensional stability than wood, no wood knots, no cracks, warping, and deformation. The product can be made into a variety of colors, and the surface can be kept fresh for a long time without secondary paint.

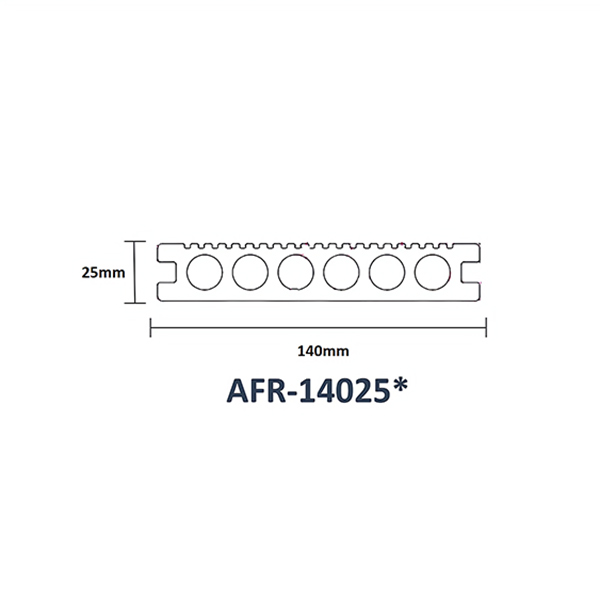

![]()

Processing performance: It has the secondary processing properties of wood, such as sawing, planing, bonding, fixing with nails or screws, and various profiles are standardized and standard, and the construction and installation are fast and convenient. Through conventional operations, it can be processed into various facilities and products.