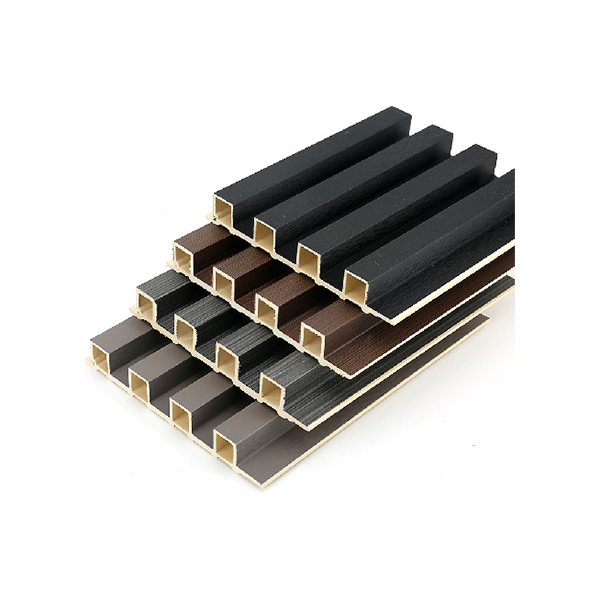

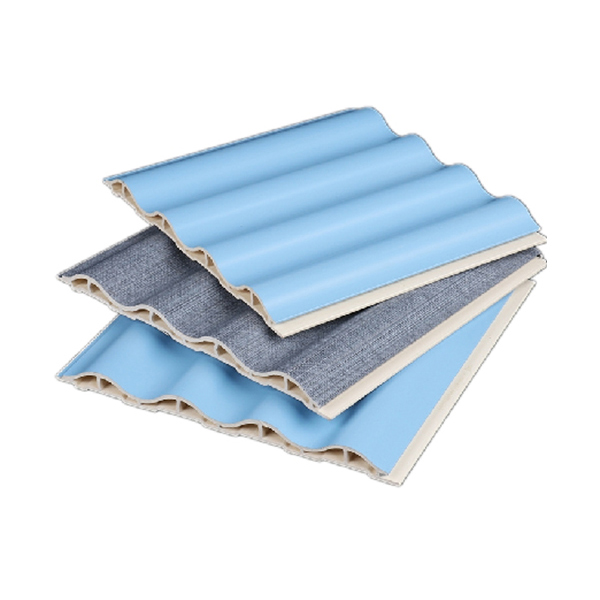

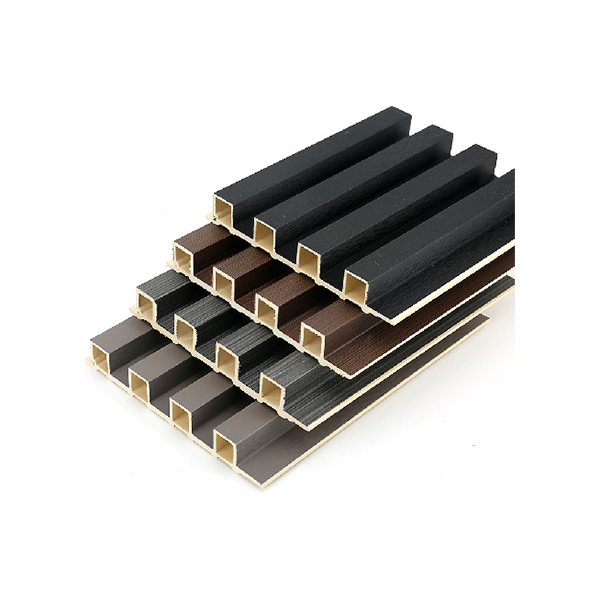

WPC Panel is a wood-plastic material, and the wood-plastic products usually made of PVC foaming process are called WPC Panel. The main raw material of WPC Panel is a new type of green environmental protection material (30% PVC+69% wood powder+1% colorant formula), WPC Panel is generally composed of two parts, the substrate and the color layer, the substrate is made of wood powder and PVC plus other Synthesis of reinforcing additives, and the color layer is adhered to the surface of the substrate by PVC color films with different textures.

![]()

Will not produce deterioration, mildew, cracking, embrittlement.

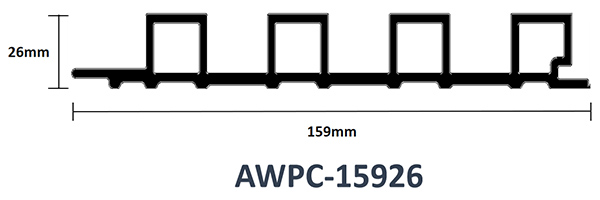

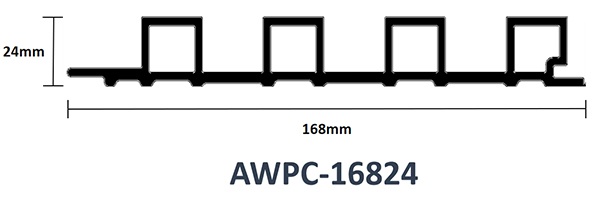

Since this product is manufactured by extrusion process, the color, size and shape of the product can be controlled according to needs, so as to truly realize on-demand customization, minimize the use cost and save forest resources.

![]()

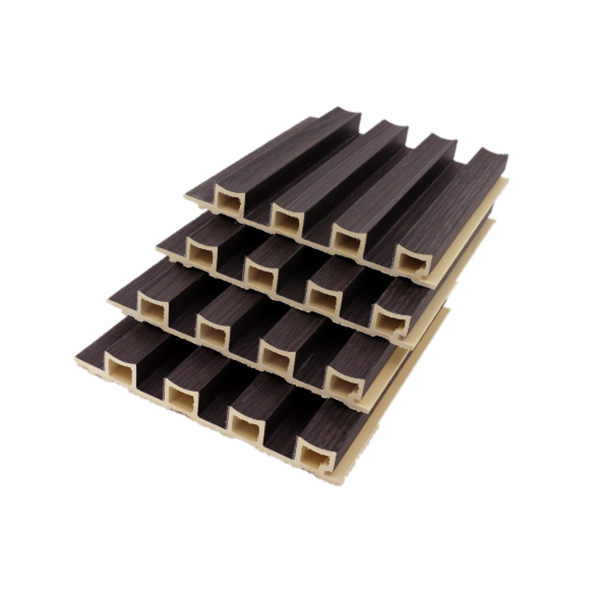

Can be recycled and reused

Because both wood fiber and resin can be recycled and reused, it is a truly sustainable emerging industry. High-quality ecological wood material can effectively remove the natural defects of natural wood, and has the functions of waterproof, fireproof, anti-corrosion, and termite prevention. It can be used as a substitute for wood in various decorative environments. It not only has the texture of wood, but also has higher performance than wood.

![]()

Not easily deformed or cracked.

Because the main components of this product are wood, broken wood and slag wood, the texture is the same as that of solid wood, and it can be nailed, drilled, ground, sawed, planed, painted, and not easily deformed or cracked. The unique production process and technology can reduce the loss of raw materials to zero.

It is a green synthetic material in the true sense.

Ecological wood materials and products are respected because they have outstanding environmental protection functions, can be recycled, and contain almost no harmful substances and toxic gas volatilization. Lower than the national standard (the national standard is 1.5mg/L), it is a green synthetic material in the true sense.